skip to main |

skip to sidebar

An Attitude of Gratitude...

Happy Thanksgiving from everyone here at Technifold USA!

"Gratefulness is the key to a happy life that we hold in our hands,

because if we are not grateful, then no matter how much we have

we will not be happy -- because we will always want to have

something else or something more." Brother David Steindl-Rast

We'll be CLOSED for the holiday

Thursday Nov 26th and Friday Nov 27th

******************************************************

How to Trim Problem Paper

In the perfect world, every sheet of paper is perfectly square

and each sheet is the same as the next. In our world, we

know this to be perhaps the exception. Maybe the paper

wasn't stored right, maybe it distorted after printing,

maybe it's a deckle edge sheet, the converter did a

lousy job...etc.

Whatever the reason, sometimes you're faced with having

to trim a job where sheet-to-sheet register seems

impossible when guillotine cutting. The recommended

solution is to obviously trim the stock before printing.

Sometimes this is just not possible...you've just got to

print the full sheet as it is.

Aside from die-cutting the piece, there is a way to

deal with this. Andrew Brennan of Delaware submitted this

tip and I've used a variation on this myself. A warning from

Andrew and me: use extreme care and if your paper

cutter manufacturer does not recommend doing this,

or they have an alternative solution, and by all means

follow their suggestions to avoid personal or machine

damage and inury! Common sense should prevail.

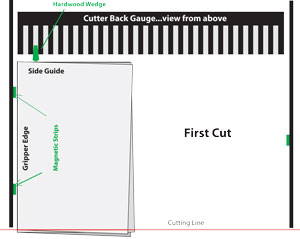

First: Construct or buy a hardwood wedge and insert it

in the cutter backgauge at the exact point

where the side guide would have pulled the sheet.

(image below)

Place magnetic strips on the cutter side at points

where the grippers would have grabbed the sheet.

Be sure both the wedge and the strips go

completely to the bottom of the cutter table so

sheets don't slide underneath, and you don't want

them to ride above either. Then make your first cut.

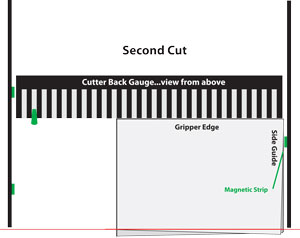

Next, rotate the stock as shown below to cut away

the tail of the sheet opposite the gripper.

Now you have two square edges to work with.

Depending on the job, you might carefully finish the cutting

while leaving all the objects in OR you might do

these first two cuts, set the lifts aside and do the

final trimming in a second pass. In either case,

don't forget to remove all objects before continuing

on to the next job.

This technique works surprisingly well, but let's hope

you don't have to pull it out of the hat too often!

******************************************************

******************************************************

Point of View

A thankful heart is not only the greatest virtue,

but the parent of all other virtues.

Cicero

What we're really talking about is a wonderful day set aside

on the fourth Thursday of November when no one diets.

I mean, why else would they call it Thanksgiving?

Erma Bombeck

Another No-Cost Business Tool from Google

The new Google Voice product gathers all your calls from your

various phones, which can then be accessed from your home,

office or cell phone.

If you ignore a voice mail, it is transcribed and sent to you as

an e-mail. And Voice lets you make free conference calls and

cheap international calls. To get started with the service,

you set up a personal Voice Web page, where you link your

home, work and cell numbers with a new number given to

you by Voice.

The new number link is used because Voice is still somewhat

under development. Before long, they will have number

portability so you won't have to use the number link they

give you to start. When one of the designated phones rings,

you can pick up whichever phone is most convenient.

You can press * to make all the phones ring again. Voice

does a pretty good job of recognizing words in a

voice mail and transcribing them. Depending on the

clarity of the speaker's diction, it could get a word or two

wrong, but generally the meaning of the message is

not changed.

You can sign up for the service at google.com/voice.

Right now, there is a waiting list.

******************************************************

******************************************************

Point of View

A mind troubled by doubt cannot focus on the course to victory.

Arthur Golden

A great marriage is not when the perfect couple comes together.

It is when an imperfect couple learns to enjoy their differences.

Dave Meurer

******************************************************

Need to Segregate Digital Work from Offset?

Or do you simply need to streamline your digital operation?

Check out the Speedcreaser here.

It's a low-cost creasing and/or

It's a low-cost creasing and/or

micro perforating solution

specifically designed for

the short-run department

or copy shop.

Currently we have customers using these in all

sorts of normal digital applications--flyers, brochures,

book covers as well as the unusual such as

creasing boxes and wrappers for promotional products.

The Speedcreaser can also be run inline with right

angle sections from folding machines, turning unused

or little-used items into productive pieces.

The Auto Feed version can also be used as a

feeder for various equipment.

Call Mark at 401-364-3735 or contact us with your questions.

******************************************************

George Foreman Hands a Knockout to Andre

"Why did you name all your sons George?"

"Why did you name all your sons George?"

is one of the most-asked questions put

to this boxing and business champ (and no,

I did NOT ask him and no, I'm not that

tall...he is sitting in the photo at left,

handing me a copy of

his latest book

Knockout Entrepreneur.)

His exchange with the reporter

went something as follows:

"Do you know Ali?"

Yes.

"Do you know Holyfield?"

Yes.

"Do you know Joe Frazier and Ken Norton?"

Yes.

"Well, let all those guys hit YOU in the head and see how

many names you can remember!"

In his book, Foreman says one of the biggest obstacles to

success is fear of taking a risk and the desire to stay in your

comfort zone. While making his comeback, he found his right

hand had weakened. Normally a boxer moves in tight circles

to the left as he moves around the ring. Foreman decided to

work on moving to the right, and worked twice as hard

on his left hand.

Challengers in the ring who had studied his old films (where

he moved to the left) were surprised when they found a

strong left-handed George moving to the right. He credits

that change in fundamentals with taking him back to the top.

He took a weakness and turned it into an opportunity.

"There's no shame in changing," says Foreman. His advice:

ask probing questions..."How can I do what I do better...

am I problem oriented or solution oriented?"

Hmmm...I think he's been reading our newsletters!

If you ever get the chance to hear big George speak, do it.

He's the real deal...an authentic, engaging, funny and

inspirational man driven by his faith, family and community.

******************************************************

Fold Roller Washes

A reader asked our opinion on using MRC (metering roller cleaner)

for folding machine fold rollers. Mark did a little research on the

topic, and here's what we found.

Most of us are inclined to lump all combination style fold rollers

into one rubber+steel category. But rubber is a very broad

category and in fact there are many types of vulcanized

rubber, polyurethanes and foams that are used in fold rollers,

even within the same makes and models.

So MRC, a 'rubber' roller cleaner, should be OK to use, right?

Not so fast. The rubber used in metering rollers is different

than fold roller rubber, and using MRC can damage your

fold rollers.

The first, best course of action is to check with the

manufacturer of your folder. Technology and materials

are changing all the time and you don't want to

inadvertently damage thousands of dollars of rollers.

"We've always done it that way" can be an expensive

motto, so double check whether that press wash or MRC

is compatible with your fold roller rubber.

MBO and Horizon techs recommend using Varn VWM, which

will remove both solvent-soluble and water-soluble glazes

in one washup. You'll get both types of build-up on

fold rollers, so it's convenient to have a one-step wash.

VWM can be mixed with 20 to 50% water for best results.

A Baum technician suggests using Surewash from RBP

Chemical on their fold rollers. Wayne Pagel of Kepes,

a specialist in fold rollers, cautions us to avoid rubber roller

(MRC) or type wash, and stick with a cleaner designed for

the type of rubber in your fold rollers.

As we discussed last week, running tough jobs like

aqueous will highlight worn or dirty fold rollers and you'll

want to clean more frequently when running tough jobs.

Just be sure to clean them with the right solution.

******************************************************

******************************************************

Point of View

Whatever you are ready for is ready for you.

Mark Victor Hansen

The real voyage of discovery consists not in seeing

new landscapes, but in having new eyes.

Marcel Proust

******************************************************

Web Press Headaches?

Is scoring on your web presses

Is scoring on your web presses

giving you fits?

Want to eliminate a separate,

offline scoring operation?

Then give Mark a call at

401-364-3735 or email

Mark@technifoldusa.com

The Web Creaser uses our Tri-Creaser technology,

adapted for web press speeds and installation requirements.

We can quickly outfit any web press.

'I Hate People'...

Though co-workers can be wonderful, you could be thinking

that some of them are a pain in the neck.

Like 'em or not, they're here to stay. You might as well

decide how they can help you or how you can avoid being

distracted by them. So say business writers Jonathan Littman

and Marc Hershon in their often-humorous book, which is

about dealing with various types in order to "get what

you want out of your job." So far, their I Hate People ...

has gained great reviews.

They do make a point when they say the person who has your

best interests at heart is probably the one sitting in your own chair.They recommend "solocrafting," which means moving forward with your work under any conditions.

What they advise:

Stop talking. Start doing. Stop asking (for whatever). And,

make them (the supervisors and co-workers) believe in you.

In other words, the writers of this humorous book are champions

of the entrepreneurial spirit in day-to-day shop or office life.

They also say teams with more than three to five competent

people are not very effective and can stifle your creativity.

Whether or not that's the case, the authors admit they don't

have all the answers.

You might find the book controversial, but at least it will

get you thinking.

******************************************************

******************************************************

Point of View

If your ship doesn't come in, swim out to it.

~ Jonathan Winters

One of the best ways to persuade others is with your ears,

by listening to them.

~ Dean Rusk

******************************************************

Folding Aqueous Coated Jobs...Feedback Part 2

Last week we touched on a few emergency techniques.

This week: equipment and environment.

Equipment

Working with aqueous or any challenging stock will tend to

highlight any flaws or worn items on your folder. For example,

a feed table register belt gets worn and glazed over time.

Normally it might not pose a problem, but present it with a

very slick stock and the problem appears. Often it's a

simple matter of cleaning, (be careful with the chemicals

you use!) or it may be time to replace (see last weeks

suggestions.) You may also find that the side guide and

register marble combinations may need to be

finessed with a slick stock.

Your fold rollers may be working just fine...until that aqueous job.

Again, more frequent cleaning with recommended roller wash

may do the trick (more on roller washes next week.)

MBO and Stahl both make use of an "open cell" foam

as a high-grip alternative to traditional polyurethane or

urethane and steel combo rollers. The downside is that the

rollers wear faster. Kepes, a manufacturer of post-press

specialty items and replacement parts, has taken the

foam roller one step further.

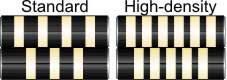

Their High Density fold roller has a simple design twist

on the standard combo

on the standard combo

fold roller. It can use

either foam or urethane,

and has the added

advantage of

decreased

marking problems--there is no steel-to-steel overlap to

cause marking as the rubber wears down. (image above)

With a high-density design for extra grip, plus urethane for

longer life (compared to foam) you now have a good,

high performance upgrade that will help with tough stock.

Questions on the fold roller issue? Give Mark a

call at 401-364-3735 or email info@technifoldusa.com

and we'll point you in the right direction.

Environment

There have plenty of books and studies done on the

Pressroom environment; suffice it to say that

humidity and temperature differences play a vital role

in the successful printing and finishing of any stock.

A few readers wrote to say that they use humidifiers

and/or vaporizers to control the relative humidity in

the vicinity of the folder. Some swear by the use

fabric softener in the mister to help with the register.

But let's back up a bit. Paper is hygroscopic: it will either

take up moisture or release moisture into the environment

to reach the same state of humidity as the surroundings.

When it stops releasing or absorbing moisture, it is

at equilibrium. For best printing (and subsequent

finishing) results, paper should be at this state of

equilibrium before printing. Also, the paper should

be at the same temperature as the pressroom.

Sounds easy, right? Well, relative humidity changes with

the air temperature. Warm air holds more moisture than cool air.

A 70 degree room will hold more moisture than a 55 degree room,

hence the term "relative humidity." In the US, relative humidity

(RH for short) can vary form 10-90% depending on

location and time of year.

To add to the mix: humidity and moisture content

where the paper is manufactured make a difference in

how the paper will perform. Sooo...to simplify things,

most paper companies manufacture so that the end

user (the printer) gets best result at an RH of about

40 to 50%. Got all that?

If you haven't already done so, a study of your

press and bindery environment is a good place to

start. If no standards and controls exist,

a changing environment will make it harder to

troubleshoot any other items. For instance, say

your RH is 25% one day and 45% the next. How

will that affect job print quality, aqueous coating

and drying? A job that runs perfectly one day may be

totally different and mis-register the next. The operator

ends up fighting a "folder" problem that is really a

relative humidity problem resulting from variations in

drying, tackiness, curl, etc.

It's a complex subject. Avoiding it will cost you

tens of thousands of dollars over the years, not

to mention endless aggravation. Paper manufacturers are a

good place to start, and there are usually very specific

recommendations for preparing various papers for

printing.

Although no single source will give you all the answers

you need, (unless you get very lucky,) by instituting

standards, you chip away at the seemingly endless variables

that can affect your production.

Next week...manufacturer recommended solutions for

cleaning fold rollers.

******************************************************